Arty 75H Special Child Resistant Packaging

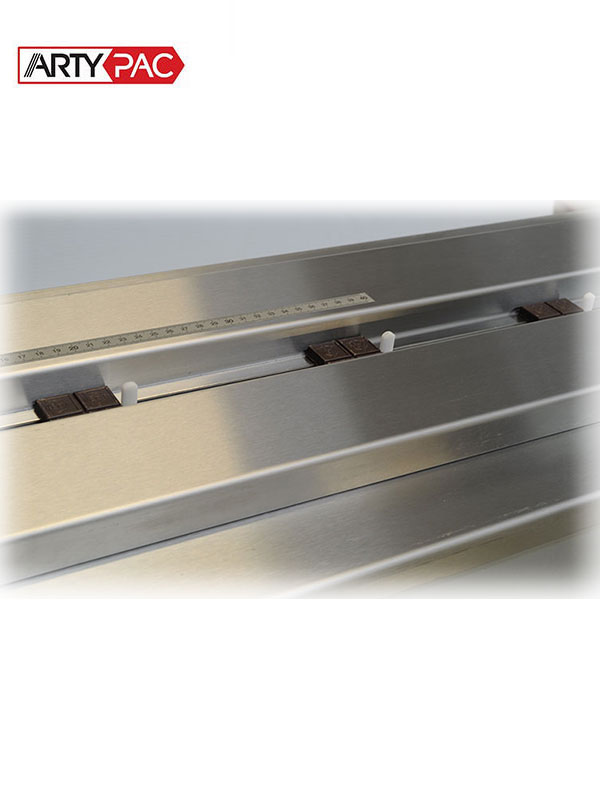

Fully Automated High Speed Horizontal Flow Wrapper

The ARTY75H is a versatile, low maintenance, horizontal flow wrapper for pillow type applications and offers hi value for the dollar.

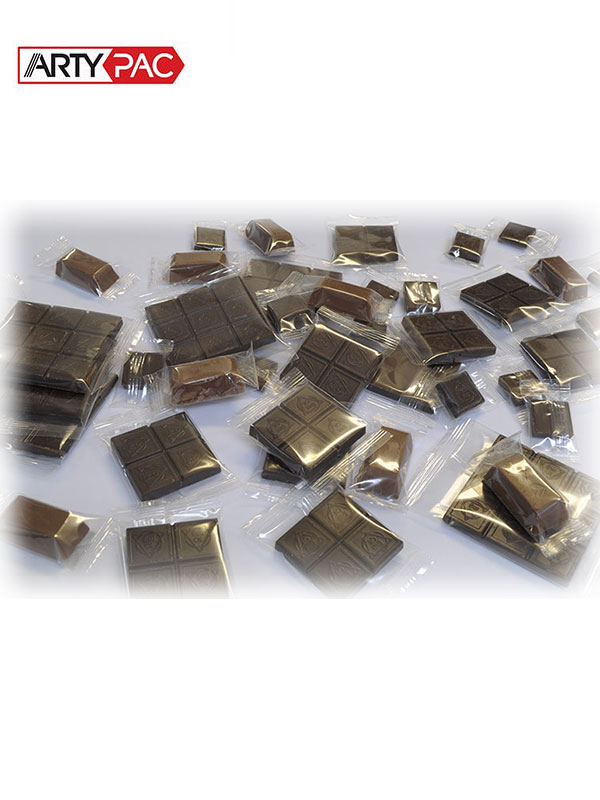

The ARTY75H is perfectly suited for the use of child resistant films up to 4 mil. in thickness.

Available with fully integrated automatic aligning and spacing infeed Smart Conveyor.

The end users are small and medium corporations in the following industries:

- Nutraceutical, pharmaceutical

- Bakeries, bread and pastries

- Specialised Cookie manufactures

- Specialised Confectionery manufacturers

- Contract packagers

- Higher speeds than the industry standards. Single jaw: 125 CPM, double jaw: 180 CPM, quadruple jaws: 360 CPM

- Low energy consumption: A single jaw machine uses only 1.3 KW per hour.

- Full stainless steel version available

- Numerous attachments available (square bottom bags, gussets, heated hole punch, print registration etc.).

- Complete line integration

- Complete set-up or changeover in just minutes and with no tools necessary.

- All parts and components are sourced in North America.

Check out the videos which shows how the ARTY 75H is the most easy-to-use and reliable machine on the market (click a link below).

- Simple, user-friendly flowrapping industrial system

- Horizontal flowrapper for pastries 'Le PÂTISSIER'

Standard Features

| Industry leading "teacher" Touch Screen HMI. |

| 4 Minute Set-ups |

| Quick loading, self-centering, reel holder. |

| Adjustable bag forming box. |

| Cut-off length adjustment by means of a hand wheel and a mechanical variator or optional Servo Drive. |

| Fin seal folding to the left or to the right. |

| Variable speed by means of a potentiometer. |

| PLC controlled |

| Digital PID temperature controllers. |

| Jaws drive torque limiter with safety switch and reset hand wheel. |

| Lugged infeed conveyor equipped with quick re-lease electromagnetic clutch. |

| Lugged infeed conveyor equipped with quick re-lease electromagnetic clutch. |

| Easy print registration. |

Optional Features

| Mobility: the machine can be equipped with four castors and four legs. |

| Inclined exit belted conveyor. |

| Collating turntable. |

| Second reel holder. |

| Punching displaying holes. |

| Opening notch punch. |

| Gusseting attachment. |

| Flat bottom bag attachment. |

| Gas flush. |

| Static eliminators. |

| Date coders and inline printers. |

All functions are PLC controlled and the machine is equipped with a user friendly touch screen interface which can store up to 99 recipes for as many different set ups.

A frequency inverter and a three-phase motor insure accurate bag lengths and eliminate any mechanical shock

Separate control panel mounted on an articulated arm makes readily accessible data on machine status and operation.

A stainless steel version is available, as well as numerous attachments such as square bottom bags, gussets, heated hole punch, print registration, printing devices for bar codes and expiration dates

Technical Data

| Bag length | Min. 1 3/4" (45mm) | Max. 24" (610mm) | |

|---|---|---|---|

| Bag width | Min. 1" (25mm) | Max. 7" (178mm) | |

| Reel size | Max width 18" (457mm) | Max O.D. 12" (355mm) | |

| Core 3" (76mm) | |||

| Speeds up to | Single jaw: | Double jaws: | Quadruple jaws: |

| 125 bags per minute | 220 bags per minute | 400 bags per minute | |

| Power supply | 220V, 10A, single phase |