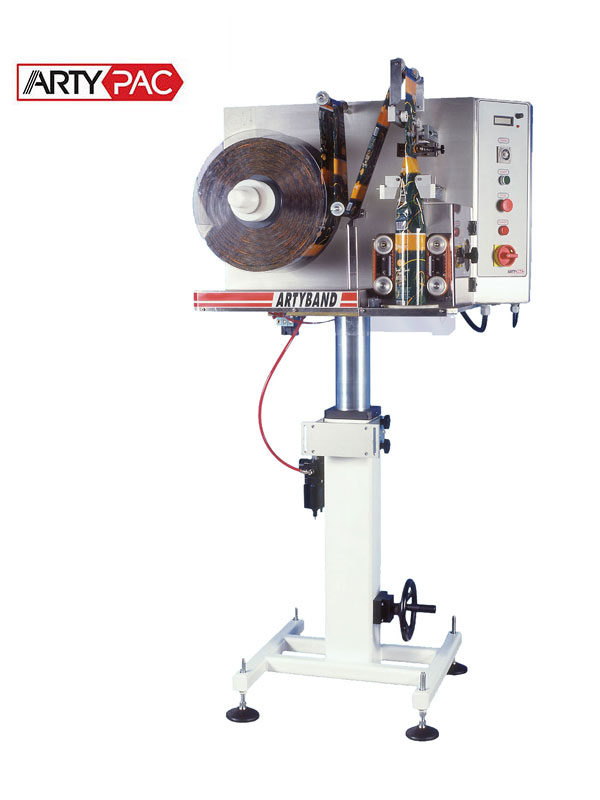

Artyband 50

Fully Automated High Speed Shrink Band Applicator

Innovative, the ARTYBAND 50, is fully automated high speed Shrink band applicator machine that incorporates a new technology which makes it one of the most easy-to-use and reliable machine on the market.

Three standard models available covering a wide variety of tamper evident and labeling applications with Precision and Versatility.

The ARTYBAND 50 is a simple-to-use and cost efficient banding machine to cut and apply shrinkable bands on:

- Bottles

- Jars

- Candles

- Plastic tubs, and other containers.

- All functions are PLC controlled

- Equipped with a user friendly touch screen interface

Check out the video which shows how the ARTYBAND 50 is the most easy-to-use and reliable machine on the market.

Standard Features

| One quick loading motorized reel holder. |

| Band feeding system by means of side belts running against a self centering mandrel. |

| Feed belts driven by two stepper motors, providing fast feed and accurate lengths. |

| Programmable lengths from 1/4" up to 12". |

| Pneumatically operated cut-off knife. |

| Polycarbonate safety guards with safety switches. |

| Tool-less indexing system pneumatically operated. |

| Optical product detector. |

| Programmable controller. |

| Speeds up to 90 bands per minute, depending on product size, indexing system and length of band. |

| Tubular steel stand protected with electrostatic paint. |

| Adjustable height by means of a hand wheel. |

| Four castors or optional leveling pads. |

| Print registration optional. |

Optional Features

| Hi efficiency shrink tunnels and conveyors. |

| All stainless steel |

PLC controller, optical product detector and easy to adjust tool-free indexing system are standard features.

Programmable lengths make neck banding or full body applications just as easy. Two stepper motors driving two pulling belts provide accurate lengths, regardless of band lenght.

Features self-centering mandrel for easy set up and fast change overs with no tools required.

Motorized and self-centering reel holder, horizontally mounted shaft to allow easy loading of reel in proper position.

Tubular stand equipped with fast height adjustment hand wheel to conform to the height of the product.

Technical Data

| Product Dia | Min. 1/4" (6mm) | Max. 5" (125mm) |

|---|---|---|

| Band width | Min. 3/8" (10mm) | Max. 8" (205mm) |

| Band length | Min. 1/4" (6mm) | Max. 12" (300mm) |

| Flat band | Max. 8" (203mm) | |

| Reel size | Max O.D. 16" (400mm) | |

| Core 5" (127mm) | ||

| Speeds up to | 200 bands per minute | |

| Power supply | 220V, 50-60 Hz, 3A, single phase |

Accessories

| 8"x8' or 8"x10' table top conveyor | Variable speed, 220V, 1.5A |

|---|---|

| Single gun heat tunnel | 220V, 16A, single phase |

| Double gun heat tunnel | 220V, 32A, single phase |

| Triple gun heat tunnel | 220V, 32A, three phases |

| Pre-shrink unit | 220V, 16A, single phase |